Home / Blog / Business Enhancement /

Fab Lab Update

| The Fabrication Lab at Emporia Main Street came online in April of last year, and it has been a wild ride taking the concept to fruition. In the past eight months, Jeremy Wharton (the Fabrication Lab Manager) has helped businesses prototype new products, supported entrepreneurs testing out concepts, worked with event organizers to support merchandise and logistical development, partnered with local businesses to mass produce concepts developed in the lab, hosted youth tours to expose people to new technology, enhanced elements of Imaginarium in the incubator space, and created new elements for internal office use. That’s a lot, and the Lab is still growing in capacity and reach. Here’s the thing about prototype development: we can’t always talk about everything going on in the lab because concepts for products are still being perfected. However, there are A LOT of things that we can talk about. The technology and support in the lab is helping entrepreneurs take concepts to fruition here at home, and local businesses now have a place to go when they have an idea for a new product or service. We aren’t going to list everything made (for a variety of reasons, including the fact that this would be a super long newsletter), but this will give you some idea of lab capacity. With that, let’s cover some of the 2022 products/items that ran through the lab and highlight the tech and processes behind the items created: |

|

| One of the issues small businesses have is inventory management. Trying to determine how much inventory you need on hand can be difficult, particularly when you are dealing with products that are targeting event participants. The Unbound Gravel route map was printed in two different sizes and promoted as an option for the Unbound Gravel event. The project utilized the wide format printer on poster paper with use of the cutter machine to size the area down. The proof of concept was very successful and highlights the inventory flexibility that can occur if businesses produce select items in house with a “batch manufacturing” philosophy that decreases waste and reduces supply chain issues. |

|

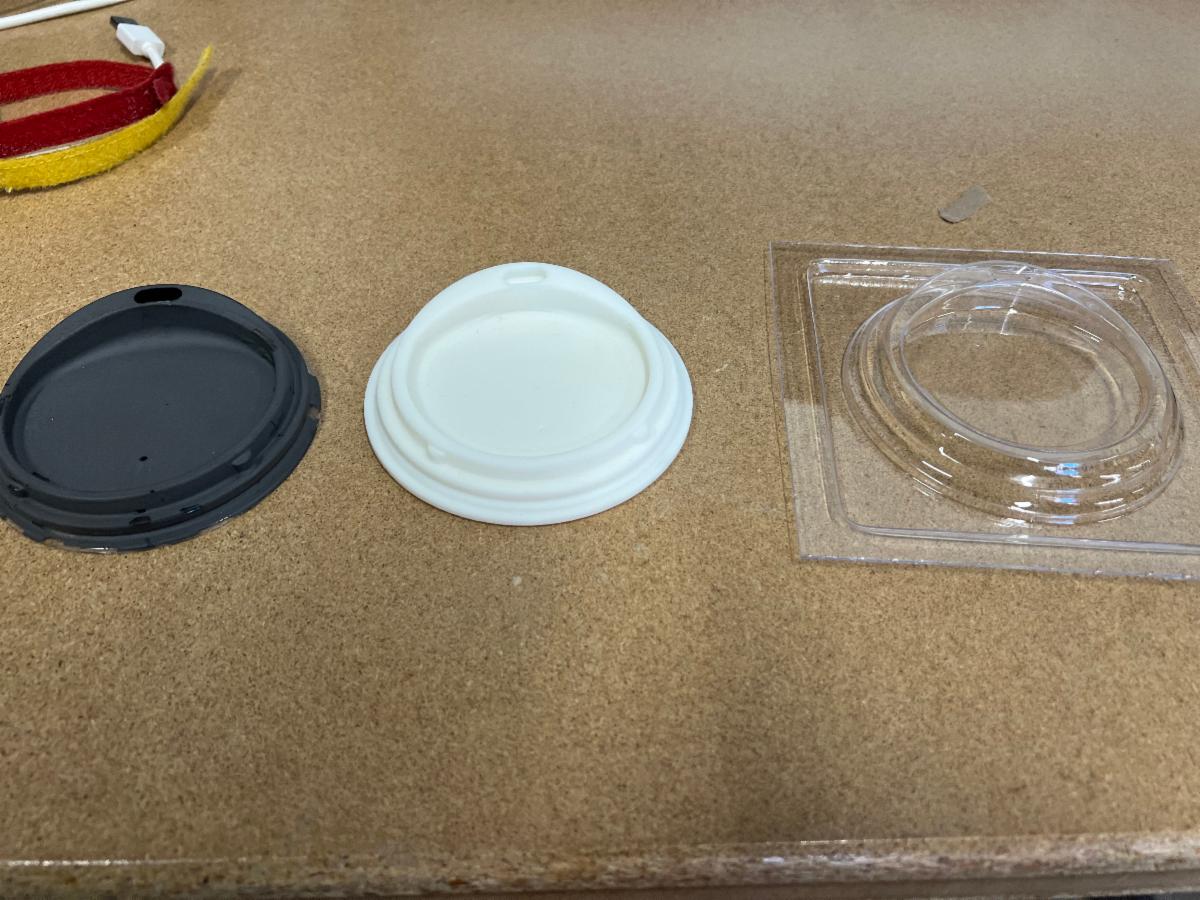

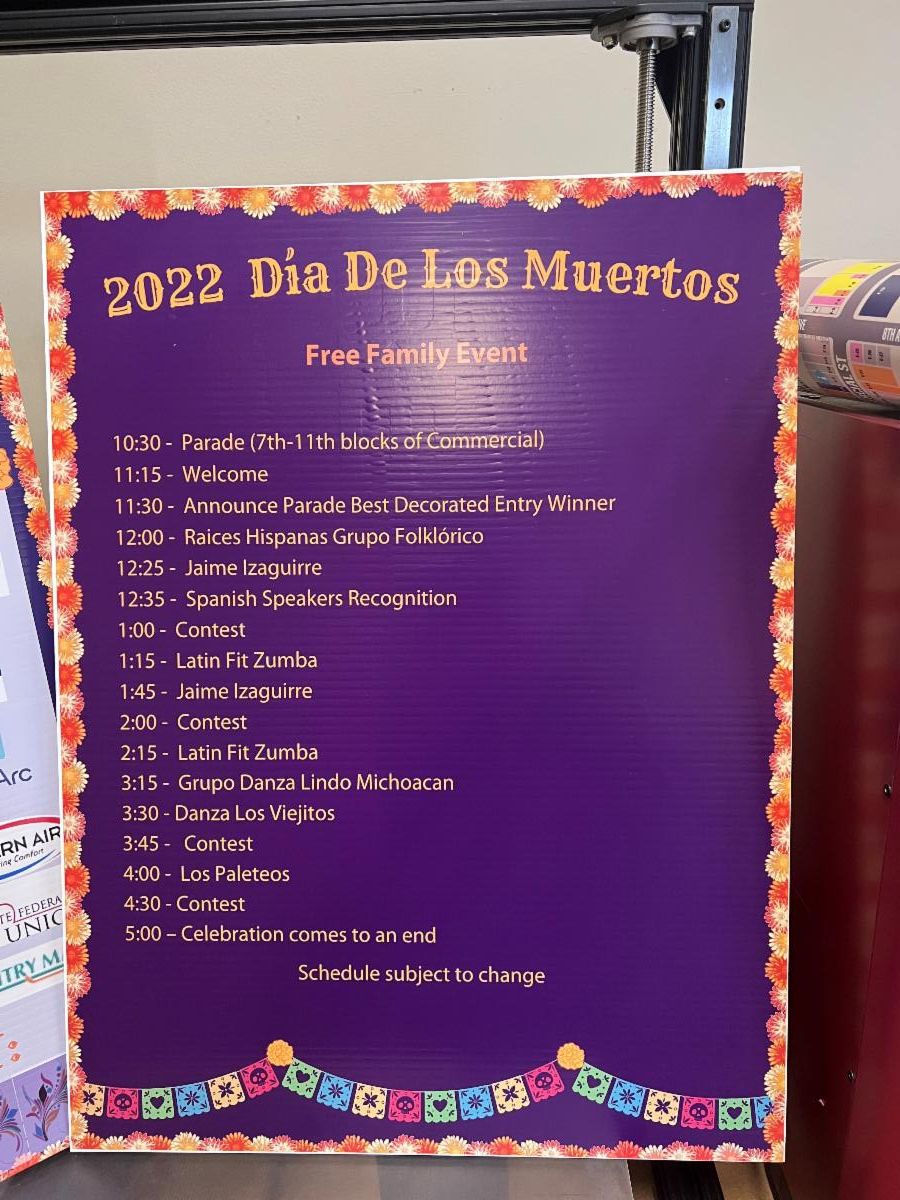

The Fabrication Lab produced several molds in 2022 for chocolate, candy, epoxy and other materials. The molds shown above were designed with 3D modeling software and printed with an SLA 3D printer. The 3D printed item then served as a negative for the Formech machine that vacuum-formed food safe plastic over the negative, creating a mold. This process allows local producers to create faster mold prototypes to satisfy local customer demands and create unique products that would be unaffordable in a traditional prototyping environment. One of the more interesting high tech devices in the Fabrication lab is the 3D scanner. The technology uses light to render a virtual three dimensional image that can be altered, printed using our PLA or SLA printers, or (with significant effort) cut out with the CNC machine in metal or plastic. This process is important for entrepreneurs that have some sort of sculpted prototype plan, for individuals that want to replicate a “one-off” type of item, or in this case a company that wanted to generate a mold of a common item to test bioplastic (biodegradable plastic) in a new product environment. A disposable coffee cup lid was scanned, the 3D image was converted into a negative, and a local business was able to use the SLA negative to mold bioplastic prototypes.  Emporia Main Street sent work to local businesses after collecting information and design specifications several times last year, but occasionally “last minute” items required in-house production. The large format printer can print on a variety of substances, including adhesive vinyl, which can be a lifesaver for local event logistical information. By acting as a development clearing house, the Fabrication Lab was able to inform the public of options for larger production jobs, while aiding in the prototyping process to reduce time and costs associated with development. The newly established pipeline kept work in the local area and improved the creative process. Emporia Main Street sent work to local businesses after collecting information and design specifications several times last year, but occasionally “last minute” items required in-house production. The large format printer can print on a variety of substances, including adhesive vinyl, which can be a lifesaver for local event logistical information. By acting as a development clearing house, the Fabrication Lab was able to inform the public of options for larger production jobs, while aiding in the prototyping process to reduce time and costs associated with development. The newly established pipeline kept work in the local area and improved the creative process. Several of our local citizens have ideas for fantastic products, but they may not have direct access to the machinery and support necessary to bring their concept to fruition in appropriate materials. This project used the CNC machine to cut a complex part out of metal after it was designed by a local engineer. Sending digital files overseas for prototyping could take several weeks, and small adjustments often mean starting over. The featured high tech support product shown above was developed in a matter of days. Several of our local citizens have ideas for fantastic products, but they may not have direct access to the machinery and support necessary to bring their concept to fruition in appropriate materials. This project used the CNC machine to cut a complex part out of metal after it was designed by a local engineer. Sending digital files overseas for prototyping could take several weeks, and small adjustments often mean starting over. The featured high tech support product shown above was developed in a matter of days. |

|

| One of the hallmarks of a good entrepreneur is they identify items that don’t currently exist in a market. In the instance pictured above, a local citizen wanted to produce a cookie cutter/press that highlighted the Emporia High School Spartans. The concept logo was altered in 3D modeling software and printed with the SLA 3D printer as a prototype test. Because we now have the 3D file, future metal versions of the cookie cutter/press could be produced in a high strength material for consistent use. |

|

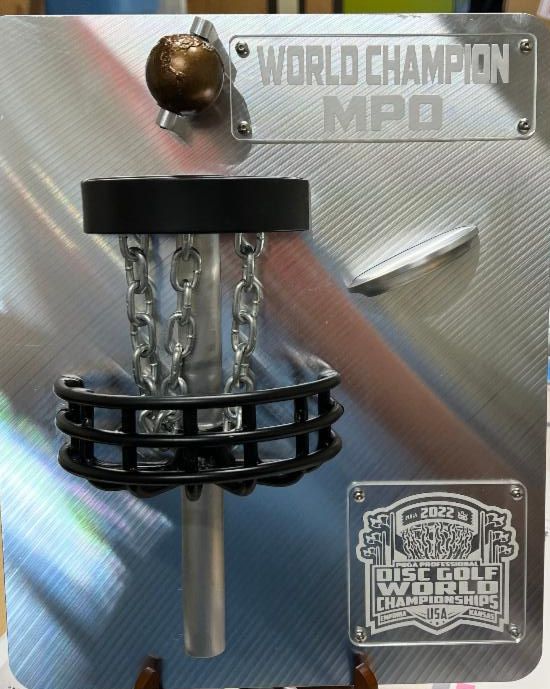

| Weighing in at just under ten pounds, the behemoth PDGA World Championship trophies were a throw back to area machine tooling roots with hand made and machined elements throughout the piece. 3D renderings, plastic prototype printing, CNC metal millwork, laser-etched items, and much more were part of this complex piece that was designed in conjunction with folks from Dynamic Discs. Special events can use the Fabrication Lab for the production of all kinds of unique items to enhance their activities. Large scale events are often also businesses, and the Fabrication Lab found ways to partner with event organizers to enhance activities. |

|

Some product creation this year focused on an underserved business population: artists. Replicating small items for testing can often lead to much larger production runs for local businesses. In this instance, the printer/cutter combination in the Fabrication lab was able to test sticker designs for larger batches through local businesses. |

| Creating 3D models for concepts can help local businesses with future expansion plans. Extending a brand often means standing out on a shelf, or in this case among other tap handles. Though not in the final color scheme (obviously), identifying shapes and sizing can enhance communication, decrease time spent in development, and reduce costs for larger scale production runs. This prototyping process used a large format 3D printer, an SLA 3D printer and design software to provide a test shape for a local business considering product expansion. |

|

| Some prototype processes don’t involve creation of a finished product, but they instead focus on product support. The packaging system shown above is cardboard that was cut and shaped using a CO2 laser system. This process allows a local business to create custom gift sets with local products on a small test scale before moving to larger custom runs. For local businesses, custom product creation and combining different products in custom gift sets can prevent a disturbing trend called “showrooming”. Some customers will visit physical store locations and check out items in person, and then attempt to find that same item online for a lower price. Using custom packaging and locally produced products can emphasize the unique product mix within local businesses and encourage destination shopping by highlighting the entrepreneurs claim of exclusivity. |

|

| Community pride product development can sometimes lead to additional training. This year’s custom community maps were designed and produced inside the Fabrication Lab. The wide format printer can print on canvas, and with a little extra training, the canvas could be stretched on a basic frame. The production of this item was an example of R & D (ripoff and duplicate). We saw community maps in other cities, found a way through software solutions to create and customize a map, and went from ideation to production fairly quickly. Other local businesses have had similar product journeys expedited by the Fabrication Lab. If you see something that you want to customize for your own purposes, the lab may be a conduit to producing your own unique products. |

|

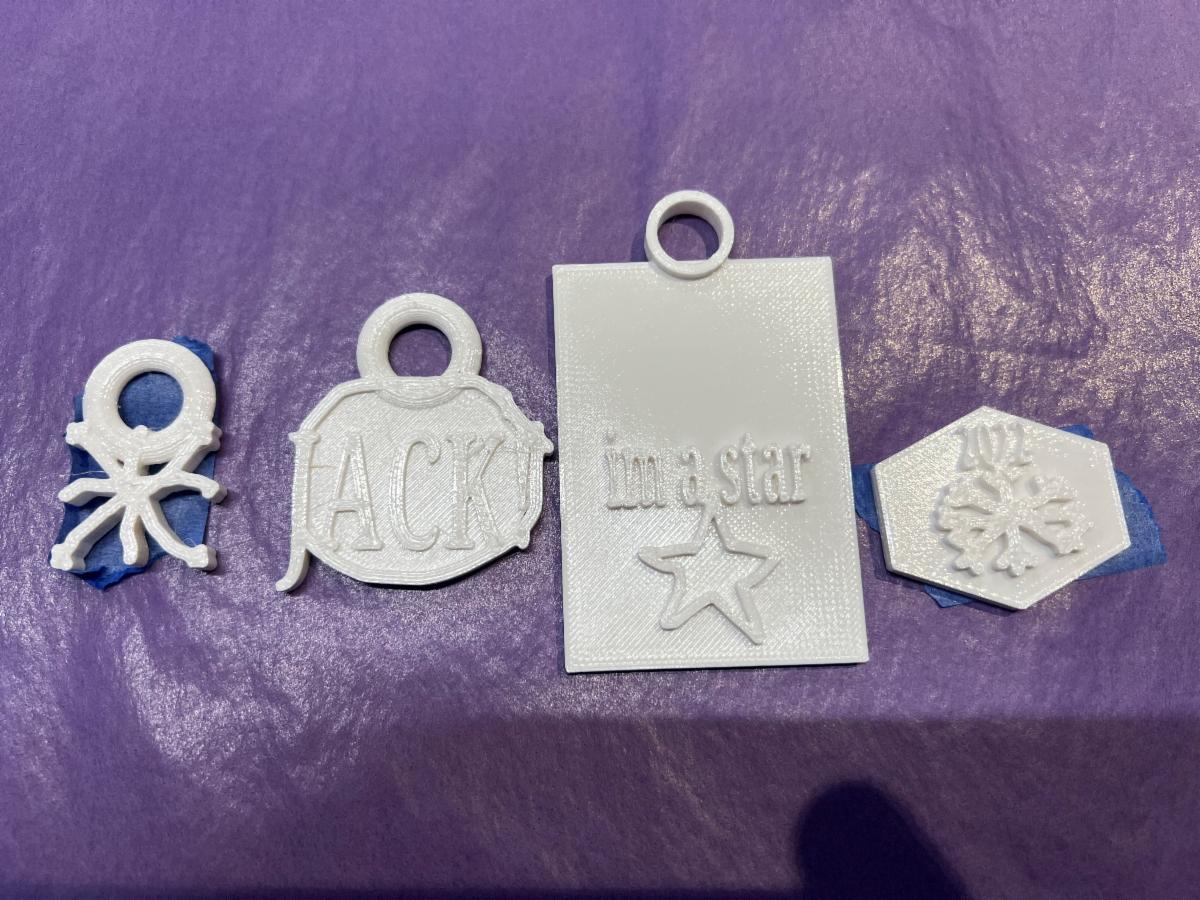

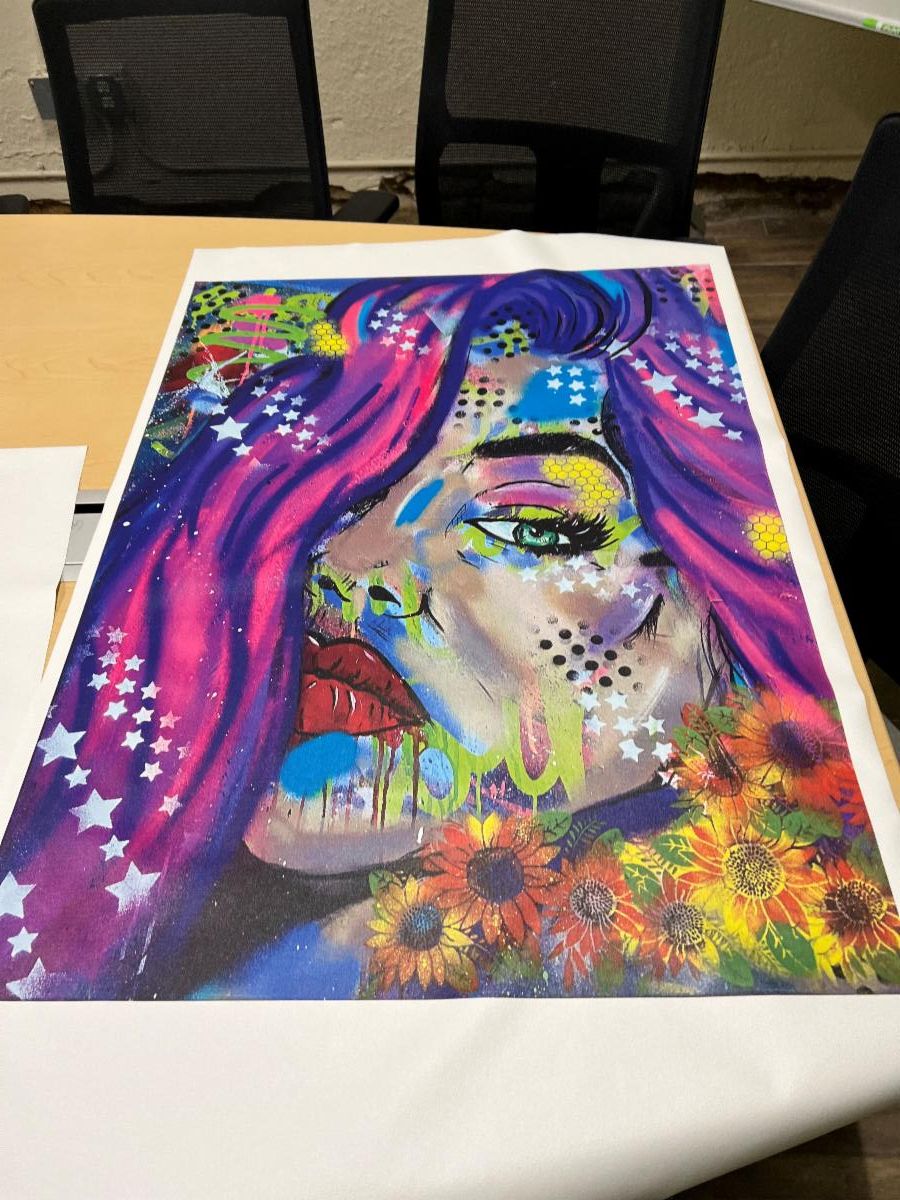

The Fabrication Lab works with Imaginarim on multiple projects. The photo above are some 3D printed ornaments that students designed, and the Fabrication Lab printed. Providing access to tech exposes local kids with all kinds of future opportunities! Artists often produce stunning work that is unique and labor intensive. Through the Fabrication Lab we were able to test reproducing artwork with high resolution photos and resizing/reproducing on printed canvas. High quality reprints can provide artists with more sustainable conduits for income while generating affordable local art for a broader audience. This particular project was completed in conjunction with an artist participating in the Emporia First Friday Walk. Artists often produce stunning work that is unique and labor intensive. Through the Fabrication Lab we were able to test reproducing artwork with high resolution photos and resizing/reproducing on printed canvas. High quality reprints can provide artists with more sustainable conduits for income while generating affordable local art for a broader audience. This particular project was completed in conjunction with an artist participating in the Emporia First Friday Walk. Some Fabrication Lab projects retrofit existing products to meet local needs. We love that people walk their dogs downtown, but we have received complaints when people forgot to pick up after their pets. The dog waste boxes have helped dramatically decrease complaints, and we’ve received positive feedback from businesses, dog walkers, community members, and City staff. The six dog waste boxes downtown did not include connections that could interface with the downtown trash receptacles, and they didn’t include areas where sponsors could easily receive recognition. Jeremy Wharton used Fab Lab resources to create new connectors, alter the boxes for placement, and generate branding material which aided in project sustainability. Entrepreneurs think of problems as opportunities, and the Fab Lab enhanced our ability to solve for a community issue.The images above are a tiny sample of products produced in 2022. This year (2023) we have all kinds of new products, community pride items, new initiatives to use tech to support community members, an upcoming tech/product based series of classes for entrepreneurs (E-Tech Startup information is coming soon), and community classes to expose folks to Fabrication Lab elements in an introductory environment. Emporia Main Street is about creating real resources for local businesses and prospective entrepreneurs. Creating products and product support through the Fabrication lab is just one of many ways we are investing in all of you to generate more opportunities for growth. If you want to talk through how the Fabrication Lab can help your business create new products or support your existing activities, contact Jeremy Wharton at [email protected] |